In modern aluminum hot rolling production, continuous efforts have been made to improve dimensional accuracy, flatness, surface quality, mechanical properties, and processability of the products. In addition, automation, continuous operation, and high-efficiency control have become core elements in achieving stable and high-quality production output.

According to different product categories, hot rolling processes for aluminum materials are typically divided into the following two types:

Plate and Strip Production Process

Flat ingot scalping → Flat ingot heating → Hot rough rolling (reversible) → Hot finish rolling (non-reversible) → Cold rolling (including trimming, intermediate annealing, etc.) → Finishing (cleaning, cross cutting, tension leveling, etc.) → Heat treatment.

Medium and Thick Plate Production Process

Flat ingot heating → Hot rough rolling (reversible) → Hot finish rolling (non-reversible) → Finishing (such as sawing, etc.).

A typical operational process is supported by a well-matched set of specialized equipment designed for each production stage. From ingot preparation to hot rolling, cold rolling, and final surface treatments, every process step requires specific machinery to ensure high-quality output and efficient throughput. In the following sections, we will take a representative aluminum processing plant in China as an example to illustrate the major equipment involved in each stage, along with its technical specifications and the performance targets that these systems are expected to achieve.

Step 1: Hot Rolling Process

1. Raw Material Specifications

Flat ingot dimensions: (420-460 mm) × (1000-2000 mm) × (3600-6800 mm)

Alloy grades: 1xxx, 3xxx, 5xxx, 8xxx series.

2. Equipment Configuration

- Flat ingot scalping machine: 1 set

- Vertical pusher type flat ingot heating furnaces: 2 sets

- 2400 mm four-high reversible dual coiler hot rolling line: 1 set

3. Process Flow and Parameters

Flat Ingot Scalping

This process removes surface segregation, inclusions, scabs, and cracks, aiming to reduce surface defects caused by metal or non-metallic inclusions and enhance surface quality. A flat ingot of size 480×1500×6000 mm (11.66 tons) is milled on both faces and sides using a scalping machine with an operating speed of 0.2 m/s. The maximum thickness removed is 6 mm, generating approximately 383 kg of aluminum chips per ingot, equivalent to 32.8 kg of chips per ton of aluminum.

Flat Ingot Heating

Scalped ingots are heated in a vertical-pusher type furnace at temperatures between 350℃ and 550℃ for 5 to 8 hours. Each furnace has five zones, each equipped with a high-volume air circulation fan at the top operating at 10–20 m/s. Compressed air consumption is 20 m³/min. There are 20 natural gas burners across four heating zones, mounted on both upper sides of the furnace, with a natural gas consumption of approximately 1200 Nm³/h.

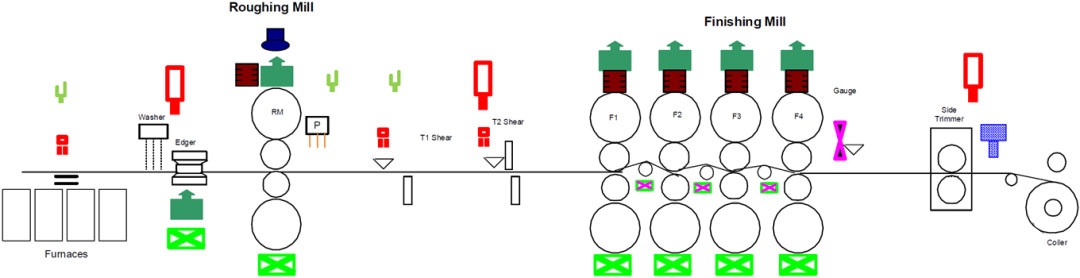

Hot Rough Rolling

The heated ingots (480×1500×6000 mm) are passed through a four-high reversible hot rolling mill. Maximum rolling speed is up to 230 m/s. After 5–13 passes, the ingot is reduced to a slab of 20–160 mm in thickness.

Hot Finish Rolling

Slabs from hot rough rolling are then processed through the finish rolling mill with speeds reaching 480 m/s. After 10–18 passes, the final coil thickness is 2.5–16 mm.

Step 2: Cold Rolling Process

1. Input Material Specifications

- Thickness: 2.5–15 mm

- Width: 880–2000 mm

- Coil diameter: φ610~φ2000 mm

- Weight: 12.5 tons

2. Equipment Configuration

- 2000 mm four-high reversible cold rolling mills: 2 sets

- 40-ton intermediate and final annealing furnaces: 6 sets

- 20 m medium-thickness precision sawing machines: 2 sets

- CNC roll grinders: 2 sets

3. Process Flow and Parameters

(1) Cold Rolling

Hot-rolled coils of 2–15 mm thickness are cold rolled on four-high non-reversible cold rolling mills through 3–6 passes to produce a final thickness of 0.25–0.7 mm.

The rolling process uses computer control for flatness (AFC), thickness (AGC), and tension (ATC). Rolling speed ranges from 5–20 m/s and can reach 25–40 m/s in tandem rolling. Reduction ratio is typically 90%–95%.

(2) Intermediate Annealing

To eliminate work hardening after cold rolling, intermediate annealing is carried out for some coils. Annealing temperature is 315–500℃, with a holding time of 1–3 hours. The annealing furnace is electric-heated, equipped with three high-flow fans at the top (10–20 m/s wind speed). Total heater power is 1080 kW. Compressed air consumption is 20 Nm³/h.

(3) Final Annealing

After cold rolling, final products undergo annealing at 260–490℃ with a holding time of 1–5 hours. For aluminum foil, the cooling rate must be less than 15℃/h, and the discharge temperature must not exceed 60℃. For other thicknesses, the maximum discharge temperature is 100℃.

Step 3: Finishing Process

1. Final Product Specifications

- Thickness: 0.27–0.7 mm

- Width: 880–1900 mm

- Coil diameter: φ610~φ1800 mm

- Weight: 12.5 tons

2. Equipment Configuration

- 2000 mm cross-cutting lines (2–12 mm): 2 sets

- 2000 mm tension leveling lines (0.1–2.5 mm): 2 sets

- 2000 mm cross-cutting lines (0.1–2.5 mm): 2 sets

- 2000 cm thick plate straightening lines: 2 sets

- 2000 mm automatic coil packaging lines: 2 sets

- CNC roll grinders: 2 sets

3. Process Flow and Parameters

-

Cross-Cutting Line

Used for precision transverse cutting of 2–12 mm thick aluminum or alloy coils. Maximum shear length reaches 11 m. -

Tension Leveling Line:

Under 2.0–20 kN tension applied by tension rollers, coils pass through small-diameter bending rolls alternately arranged, inducing plastic extension to equalize fiber length and improve flatness. Line speed reaches 200 m/min. -

Thick Plate Straightening Line:

Rollers are angled to the movement direction of the product. Two or three large driving rolls are powered by motors, while smaller passive rolls rotate via friction. Their positions can be adjusted to apply appropriate compression, bending, and flattening. Maximum straightening force: 30 MN.

Step 4: Deep Processing Technology

1. Brushed Finish Process

Includes degreasing, abrasive brushing, and rinsing. After anodizing, a brushed texture is created using 0.1 mm stainless steel wires or abrasive belts, forming a metallic oxide layer with visible hairline texture and matte shine. It enhances appearance and corrosion resistance.

2. Etching Process

The surface is first ground with jujube charcoal to remove grease and scratches. Then, patterns are screen-printed (ink types: 80-39, 80-59, 80-49) and oven-dried. The back is masked and edges taped. The etched solution (50% ferric chloride + 50% copper sulfate + water) is maintained at 15–20℃. Aluminum sheets are etched flat for 15–20 minutes. Red residues must be brushed away during bubbling.

3. Electrophoretic Coating Process

Process steps: degreasing → hot water rinse → water rinse → neutralizing → water rinse → anodizing → water rinse → electrolytic coloring → hot water rinse → water rinse → electrophoresis → water rinse → drying.

The electrophoresis bath (7%–9% solid content, 20–25℃, pH 8.0–8.8, resistivity 1500–2500 Ω·cm, DC voltage 80–250V, current density 15–50 A/m²) forms a 7–12 μm acrylic resin film over the anodized layer within 1–3 minutes.