Energy demand continues to grow worldwide, and industries are under increasing pressure to improve efficiency while transitioning toward cleaner energy solutions. One promising pathway is oil-coal slurry, a fuel made by blending residual oil with pulverized coal into a uniform mixture. This slurry can be processed into high-value energy products or used directly as a flexible fuel.

By combining two abundant energy sources—oil and coal—industries can maximize resource use, reduce waste, and stabilize energy supply. However, producing a homogeneous slurry is not straightforward. The differences in physical properties between viscous oil and fine coal powder make the blending process challenging. To solve this, specialized intensive mixing technologies have been developed to ensure stable slurry quality.

The Role of Oil-Coal Slurry in Energy Utilization

Oil-coal slurry provides multiple advantages:

- Resource optimization – Residual oils that are otherwise difficult to process can be converted into usable fuel by mixing with coal.

- Stable operation – A well-prepared slurry ensures consistent downstream combustion and refining processes.

- Fuel flexibility – Industries can adapt to different grades of coal and heavy oils, enhancing energy security.

In addition, slurry production supports global efforts to reduce dependence on crude oil and to create transitional fuels that bridge conventional energy with future clean energy pathways.

Challenges in Oil-Coal Mixing

Mixing oil and coal is complex due to their different physical and thermal properties:

- Viscosity and fluidity – Residual oil has high viscosity and poor flowability, while coal exists as fine solid particles.

- Temperature differences – Hot oil interacts with cooler coal, forming a boundary layer that blocks efficient blending and slows heat transfer

- Agglomeration – Coal particles often cluster into spheres wrapped by oil, preventing proper distribution.

- Sedimentation – Coal tends to sink during mixing if not properly suspended, leading to stratification.

These issues make uniform blending difficult without specialized equipment.

Mixing Mechanisms: Dispersive and Distributive

Producing stable oil-coal slurry requires two complementary mixing mechanisms:

- Dispersive mixing: breaking down coal clusters and exposing more particle surface to the oil.

- Distributive mixing: spreading coal particles evenly throughout the oil, ensuring consistency without altering particle size.

At the same time, the process involves intensive heat exchange, where hot oil transfers heat to cold coal until balance is reached. This balance stabilizes viscosity and flowability.

Intensive Mixer Solutions for Oil-Coal Slurry

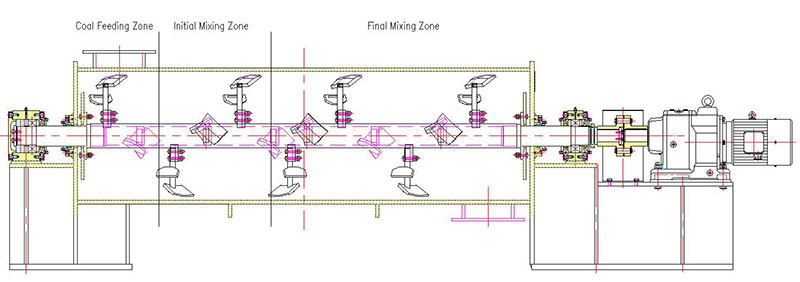

Advanced intensive mixer are designed to overcome the specific challenges of oil-coal blending. Their efficiency lies in using multiple mixing zones:

Coal Feeding Zone

- Provides steady coal delivery.

- Prevents slurry backflow into the feeder.

- Prepares coal for first contact with oil.

Initial Mixing Zone

- Oil is introduced in a controlled way to minimize boundary layers.

- Mixing tools ensure early-stage dispersion and prevent lump formation.

Final Mixing Zone

- Equipped with high-shear mixing elements for strong dispersive action.

- Prevents coal sedimentation and maintains particle suspension.

- Extends residence time, allowing complete mixing and stable slurry formation.

This zoned design ensures that oil and coal, though highly incompatible in raw form, can be transformed into a uniform and pumpable slurry.

Key Design Features of Intensive Mixers

Efficient intensive mixing relies on several important design considerations:

- Mixing element geometry – Angled and curved blades generate both axial and radial flow, preventing dead zones and sediment buildup.

- Overflow baffles – Force partial recirculation, extending residence time and improving uniformity.

- Multi-point oil injection – Reduces boundary layer size by introducing oil from multiple inlets.

- Dust and vapor control – Prevents clogging and ensures smooth, continuous operation.

Together, these features deliver better slurry stability, improved energy efficiency, and reduced downtime.

Industrial Benefits of Intensive Mixing

A uniform oil-coal slurry produced by intensive mixing delivers clear benefits:

- Stable performance – Maintains consistent viscosity and density, ensuring reliable reactor or burner operation.

- Higher efficiency – Better dispersion improves energy yield from the same feedstock.

- Reduced maintenance – Optimized mixing prevents clogging and sedimentation issues.

- Scalable technology – Intensive mixers can be adapted for different plant sizes and capacities.

- These advantages allow industries to integrate oil-coal slurry into existing processes with confidence.

Future Outlook

Although oil-coal slurry is not a long-term solution for carbon neutrality, it plays an important role as a transitional fuel. It maximizes the value of heavy oils and coal resources while industries move toward cleaner alternatives. Future developments in intensive mixing technology will focus on lowering energy consumption, improving slurry stability, and enabling broader industrial applications.

As industries adapt to changing energy landscapes, intensive mixers for oil-coal slurry will remain central to bridging the gap between traditional fuels and sustainable energy systems.

Producing oil-coal slurry is a sophisticated process requiring solutions to viscosity, heat imbalance, agglomeration, and sedimentation challenges. With advanced intensive mixing systems, these difficulties can be overcome, resulting in uniform and stable slurry production.

By enhancing efficiency, reducing waste, and offering operational flexibility, intensive mixing technology ensures oil-coal slurry remains an essential pathway in today’s evolving energy environment.