Producing high-quality dry powder fire extinguishing agents requires not only the right formulation but also the right mixing equipment. The mixer determines how well silicone oil and other additives are distributed across powder surfaces — directly affecting flowability, moisture resistance, and discharge performance of the final agent.

Recent process studies have clearly shown that the ploughshare mixer is one of the most effective tools for this type of production. It provides fast, uniform, and energy-efficient mixing while also integrating drying functions when required. For manufacturers of ABC, BC, and multi-component fire extinguishing agents, this mixer design has become an ideal choice for consistent product quality and simplified operations.

Why Mixing Quality Matters

In a typical dry powder fire extinguishing formulation, fine powders such as ammonium phosphate or sodium bicarbonate must be evenly coated with a thin layer of silicone oil. This coating prevents moisture absorption and caking, ensuring that the agent flows smoothly inside the extinguisher and discharges effectively when used.

If mixing is uneven, the silicone oil may form lumps or leave some particles uncoated, resulting in poor flowability and reduced shelf life. Traditional mixers often fail to achieve full dispersion within a reasonable time, which increases processing costs and energy use.

That’s where the ploughshare mixer stands out.

How the Ploughshare Mixer Improves the Process

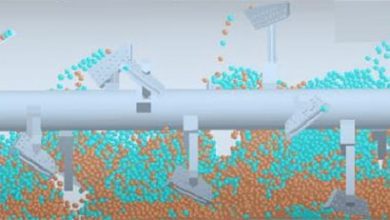

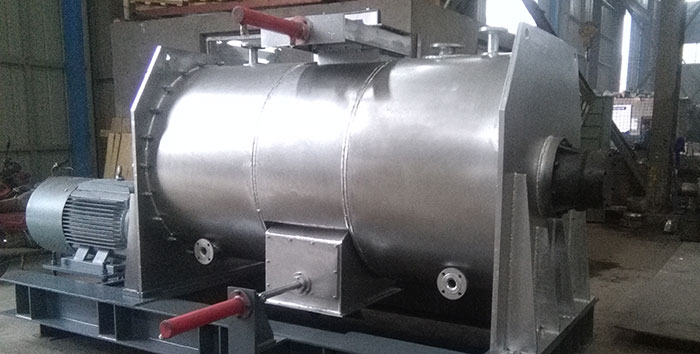

The ploughshare mixer uses a horizontal drum fitted with plough-shaped blades mounted on a central shaft. As the shaft rotates, these blades create strong three-dimensional motion — powders are lifted, thrown, and folded continuously.

This movement ensures:

- Fast and uniform mixing, even when small amounts of liquid silicone oil are added;

- No dead corners in the mixing chamber;

- Gentle handling of fine materials to avoid particle breakage.

When equipped with a heating jacket, the same system can perform mixing and drying simultaneously. This integrated design replaces separate dryers, shortens the process time, and improves production efficiency.

For most dry powder formulations, the ploughshare mixer can reach full uniformity within 30–40 minutes, compared with over an hour for ribbon or twin-shaft mixers.

Key Advantages in Fire Extinguishing Agent Production

Using a ploughshare mixer brings several clear benefits for fire extinguishing powder manufacturers:

- Uniform Silicone Oil Dispersion – Ensures every particle is evenly coated for stable hydrophobicity and improved storage life.

- Shorter Mixing Cycles – Reduces overall processing time and energy consumption.

- Integrated Drying Capability – Optional jacketed models remove moisture quickly, saving space and simplifying production lines.

- Low Residue and Easy Cleaning – Smooth internal surfaces prevent material buildup, minimizing cross-contamination between batches.

- Adaptable for Different Formulas – Handles various materials including ammonium phosphate, sodium bicarbonate, metal salts, and fine additives.

These features make the ploughshare mixer a flexible and dependable solution for both new and upgraded dry powder plants.

Practical Operating Recommendations

Based on extensive industrial testing, a few key points can help users achieve the best results:

- Feeding sequence matters – Add powders first, then gradually introduce silicone oil through a fine spray to ensure even coating.

- Control jacket temperature – For drying, maintain around 70–80 °C to achieve proper moisture removal without agglomeration.

- Avoid overfilling – Keep the load between 60–70 % of total volume for optimal movement and energy efficiency.

- Routine inspection – Regularly check blade wear and seal conditions to maintain consistent performance.

With these simple practices, the ploughshare mixer can consistently deliver high-quality, free-flowing fire extinguishing powders ready for packaging.

An Ideal Choice for Modern Production Lines

The ploughshare mixer has evolved from laboratory research to become a proven industrial standard. It combines strong mixing action with gentle particle treatment, meeting the unique needs of dry chemical agent manufacturing.

For producers looking to modernize or expand their facilities, adopting a ploughshare mixer means:

- Higher batch consistency,

- Lower operating costs,

- And a simplified, energy-saving production flow.

It’s a practical, reliable solution for achieving stable quality and improved efficiency in dry powder fire extinguishing agent production.