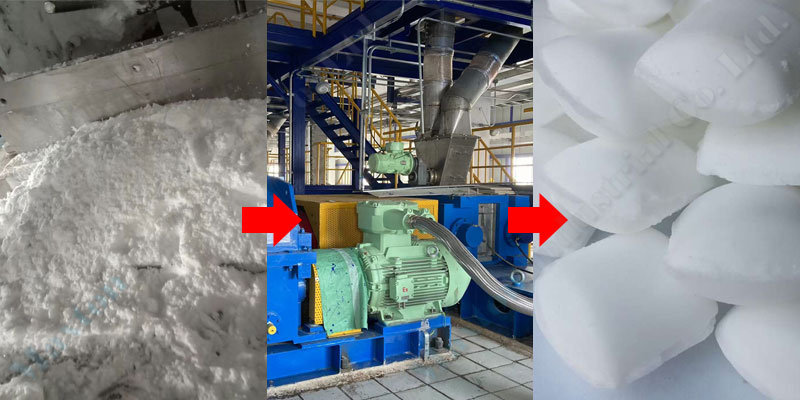

Maleic anhydride briquetting

Maxton’s roll briquette machine is an ideal machine for turning maleic anhydride to briquette, whether the maleic anhydride is from the production process or fine of the by-product, by using our strong and powerful machine, they all can be turned to briquette.

Benefit of using Maxton’s roll briquette machine

The ideal maleic anhydride briquette machine is the roll press from Maxton.

- Provides uniform and powerful pressure, pressure adjustable, ensure consistency in product quality.

High yield of formed products, reducing material wastage. - The contact surface with materials is made of carefully selected special materials, greatly extending the equipment’s lifespan.

- Excellent sealing structure, effectively reducing pollution, lowering workshop dust levels, and minimizing irritation to workers.

- Equipped with Siemens PLC system for remote control, reducing labor intensity, and ensuring worker safety.

Application of the briquette

- Used in the synthesis of dienes, pharmaceuticals, dye intermediates, polyester resins, alkyd resins, maleic acid, and other organic acids.

- Used as preservatives for fats and oils.

- Utilized in pesticides, coatings, inks, lubricant additives, paper chemicals, textile finishing agents, surfactants, and other fields.

- Using maleic anhydride as a raw material, organic and fine chemicals such as 1,4-butanediol, gamma-butyrolactone, tetrahydrofuran, maleic acid, succinic acid, and succinic anhydride can be produced.