Salt briquette machine (sodium chloride briquetting)

Maxton’s roll briquette machine is an ideal machine for turning salt (sodium chloride) to briquette, whether the salt is sea salt, coarse salt, rock salt or others from mines or solar evaporation as well as raw mine salt for industrial and domestic purposes, by using our strong and powerful machine, they all can be turned to briquette.

Optional

Salt is a kind of corrosive substance, in order to improve the long time performance, lower down maintenance cost of briquetting, special material can be chosen for contact areas for the briquetter, which all or part of them can be different grades of stainless steel, plastic, etc.

Flexible and economical

A dry briquette process for salt with near zero moisture is economical, dry feed material from an almost unlimited number of sources and without special requirements on particle size or distribution for salt makes the technology gaining increasing importance in the industry.

The fine salt particles are subjected to a sufficiently high pressure in our roller press to squeeze together and thus freeze the pure salt we used or the desired formulation.

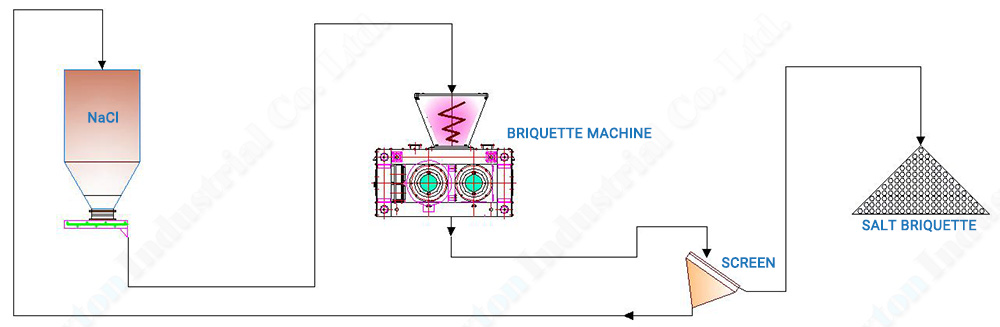

Salt briquette plant

The process consists in briquetting under pressure sodium chloride into briquette.

Generally, salt is agglomerated after the drying step which reduces the moisture to less than 0,2%. A force feeder or a gravity feeder feeds the salt between two rotating parallel rollers turning in opposite directions. This process allows the formation of briquettes.

The quality of salt determines the compression roller speed and the pressure level.

Additionally, the size range has a great influence on the choice of feeding systems in presses (gravity or force feeder).

Q&A

1. Is it easy to make salt briquette?

To obtain qualified salt briquette, high pressure briquetter is needed, besides, the size of raw material is another factor significantly affects the quality of the finished product.

2. What is the density of salt briquette?

Salt briquette density will vary from the salt purity or formula of salt used, pressure used, etc.

3. How much will a salt briquette machine cost?

It’s a hard question to answer, the price of salt briquette machines depends on many factors, only we find your specific need, we find the best machine (model). We will supply customized machines according to your very requirements.

4. What is the size of salt can be used for briquetting?

Any size.

5. Do I need to use binder when briquetting?

No, it’s a binder free way.

6. How much power will be cost when making salt briquette?

Normally the power consumption will be around 15-20kW/ton briquette.

7. I want to know the briquetting performance of my salt, is there any possible way?

Maxton supplies free test and trial services for your salt, contact us freely to know what you need and what you can get.

8. Can you guide me in setting up a whole system?

Maxton not only supplies the briquette machine for salt briquetting, but also engineering work or even EPC for a whole system. Our service includes but is not limited to consulting, engineering, project study, operation and maintenance training. Key equipments supply for a salt briquetting plant is also a flexible choice for a qualified system.

Related

Animal-licking salt block briqutte making

Snow melting salt granular briquetting