Soda ash compactor

Maxton’s roller compactor is an ideal machine for pressing soda ash into flakes or ribbon, it is a way flexible and easy to turn your soda ash light to dense type.

Flexible and economical

A dry compacting process for soda ash with near zero moisture is economical, dry and hot feed material from an almost unlimited number of sources and without special requirements on particle size or distribution for soda ash makes the technology gaining increasing importance in the industry.

The fine and high temperature soda ash particles are subjected to sufficiently high pressure in our roller compactor to squeeze together and thus turn it into a higher quality and more valuable product.

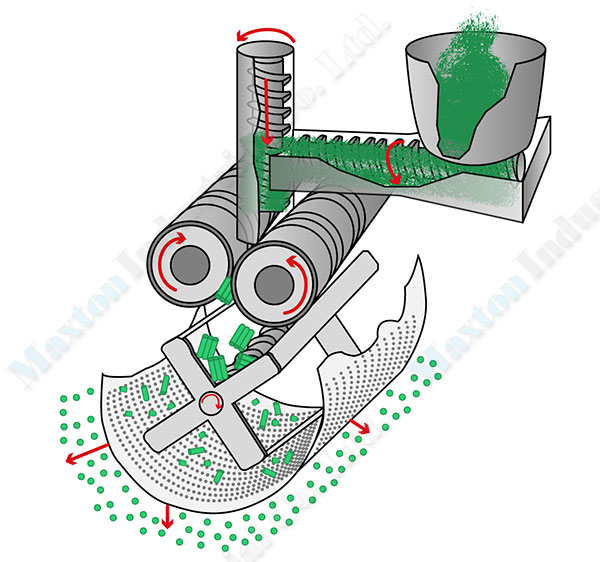

Soda ash compaction/dry granulation system

The process will turn soda ash light into soda ash dense.

The force feeder will feed the soda ash between two rotating parallel rollers turning in opposite directions. This process allows the formation of briquettes.

The quality of soda ash granular determines the compression roller speed and the pressure level, also raw material conditions like size, temperature, etc.

Additionally, the size range has a great influence on the choice of feeding systems in presses. Cooling will be implemented for the compactor to withstand the high raw material temperature.