Hydraulic briquette machine is a briquetter uses liquid pressure energy to transmit power, enabling various pressure processing techniques. It is a widely used material forming equipment in the material processing industry. It’s a common press that can work under pretty high pressure and make briquette through its mold. Widely used in industries like metugally, mining, chemical, etc.

The raw material is fed into the briquette molding box through the feeding device. Once the material in the molding box reaches an appropriate level, the upper hydraulic press head presses down to briquette the raw material. After briquetting, the lower hydraulic press head retracts, making the briquette fall into the pusher slot. Then, the lower hydraulic press head extends, pushing the briquette out, and subsequently, the upper hydraulic press head retracts, completing the entire briquetting process.

This cycle repeats continuously, compacting the raw material into briquettes. During this process, the lower hydraulic cylinder press head not only pushes the briquette but also serves as a support plate during briquetting, facilitating the briquetting of the raw material.

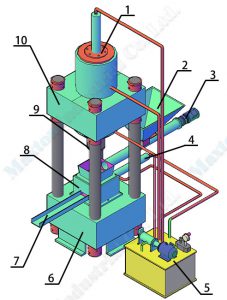

1. upper hydraulic cylinder 2. material feeding hopper 3. material feeding screw 4. lower hydraulic press head 5. hydraulic station 6. down frame 7. briquette output chute 8. molding box 9. upper hydraulic press head 10. upper frame

1. upper hydraulic cylinder 2. material feeding hopper 3. material feeding screw 4. lower hydraulic press head 5. hydraulic station 6. down frame 7. briquette output chute 8. molding box 9. upper hydraulic press head 10. upper frame

Composed of the frame, main hydraulic cylinder, pusher hydraulic cylinder, bottom plate hydraulic cylinder, matching mold frame and molds, press head, etc.

The frame consists of upper and lower beams and columns. Both the upper and lower beams are made of cast steel, connected by four columns with inner and outer nuts, bearing the tension during operation. The main hydraulic cylinder avoids using cast steel to eliminate safety hazards, ensuring the equipment’s lifespan and operational safety. The matching mold frame and molds, along with the press head, are professionally designed and manufactured with superior processing capabilities, guaranteeing the equipment’s excellent quality. The molds and briquetting machine’s punch are equipped with high-strength, wear-resistant steel that can be quickly replaced. Relevant parts are specially hardened or forged where necessary.

Composed of motor, hydraulic pump, pump protection device, professional control valve block, and piping system connected to the briquetting machine.

The design is reasonable and the quality is stable. Can be equipped with a cooling system (optional) to prevent the equipment from being unable to work continuously due to overheating oil temperatures.

Composed of electrical control cabinet along with PLC control.

Equipped with adjustable text display, the action sequence and the duration of each action are entirely controlled by the PLC system, which can be adjusted by the operator at any time, making it convenient, quick, and easy to understand.

Metal and turnings

| Model | 32-200 | 32-300 | 32-400 | 32-500 | 32-630 | 32-800 |

| Briquette diameter mm | 80-120 | 100-140 | 110-160 | 120-180 | 130-200 | 150-240 |

| Norminal Pressure (t) | 200 | 300 | 400 | 500 | 630 | 800 |

| Max. Working Pressure (Mpa) | 25 | 25 | 25 | 25 | 25 | 25 |

| Main Power (kW) | 11 | 15-22 | 22-30 | 30 | 30-37 | 67 |

| Briquette Density (iron, steel) t/m3 | 4.2-5.5 | 4.2-5.5 | 4.2-5.5 | 4.2-5.5 | 4.2-5.5 | 4.2-5.5 |

| Briquette Density (aluminum) t/m3 | 2-2.4 | 2-2.4 | 2-2.4 | 2-2.4 | 2-2.4 | 2-2.4 |

| Briquette Density (copper) t/m3 | 5.9-7.8 | 5.9-7.8 | 5.9-7.8 | 5.9-7.8 | 5.9-7.8 | 5.9-7.8 |

Salt block

| Model | Norminal Pressure (t) | Max. Working Pressure (Mpa) | Main Power (kW) | Block Weight (kg) |

| 32-100 | 100 | 25 | 7.5 | 2 |

| 32-200 | 200 | 25 | 15 | 2-5 |

| 32-300 | 300 | 25 | 22 | 4-7 |

| 32-400 | 400 | 25 | 30 | 2-10 |

| 32-500 | 500 | 25 | 30 | 5-10 |

| 32-630 | 630 | 25 | 37 | 5-15 |

| 32-720 | 720 | 25 | 45 | 10-20 |

| 32-800 | 800 | 25 | 90 | 10-30 |

Aluminum

Aluminum  Salt

Salt  Sawdust

Sawdust  Copper

Copper

In briquetting, the binder is often the unsung hero. Whether you’re compacting…

Why Make Cold Iron Ore and By-product Briquettes With the shortage of…

What is water softnter salt briquette Water softener salt briquette, also known…

What is coke fine Coke fine refers to the small-sized particles or…

Why Deoxidation in Steelmaking Deoxidation plays a dual role in the steelmaking…

What is red mud Around 1888, Austrian chemist Carl Josef Bayer developed…