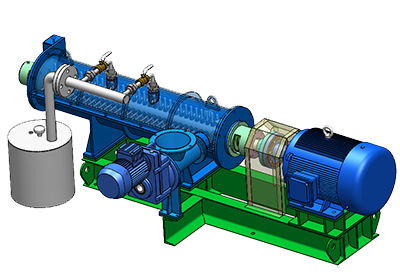

The pin mixer is a high-speed, horizontal mixing machine designed for agglomerating and micro-pelletizing fine powders. It offers excellent material densification with lower binder usage compared to disc pelletizers, making it both cost-efficient and effective for fine particle processing. Ideal for standalone use or as a pre-conditioning step before secondary agglomeration equipment, it ensures the formation of uniform, dense pellets with improved flowability, structural strength, and consistent quality across different material types.

Material is fed into the mixer through the inlet, while liquid binders are injected via specialized spray nozzles. Depending on the binder type and process requirements, the addition method may vary — in some cases involving only the inherent moisture or tackiness of the material itself, especially when working with naturally sticky substances.

Inside the chamber, a central high-speed rotor equipped with multiple pins generates intense shear and mixing forces. As the material moves forward through the mixer, it undergoes rapid agitation and tumbling, which initiates agglomeration. The combination of rotational energy and binder dispersion results in the formation of dense, spherical micro-pellets with uniform size and improved flow properties.

The finished pellets are continuously discharged through the outlet. Since the Pin Mixer is primarily designed for micro-pelletizing applications, the resulting pellet size is typically smaller than that produced by other agglomeration equipment.

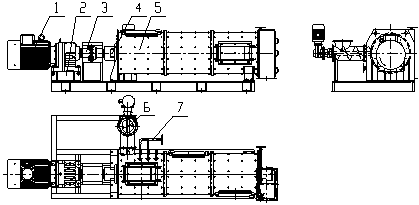

1.Motor and Reducer 2.Base Frame 3.Gear Coupling 4.Mixing Rotor 5.Mixing Drum 6.Screw Feeder 7.Liquid Addition System

The interior is lined with ultra-high molecular weight polyethylene (UHMW-PE) liners, which are bolted in place using specially designed tools to ensure interchangeability and easy maintenance.

Directly driven by motor and reducer. Enables precise and controlled material feeding.

The liquid adding system consists of flanges, fittings, ball valves, and atomizing nozzles.

The mixing tool is one of the core components of the machine. Specially shaped mixing tools, composed of paddles and blades, are fixed along the rotor shaft. These tools are wear parts and are surface-hardened with high-durability welding rods.

Another critical element is the pin, helically arranged and extending radially from the main shaft. Pins are ideal for intensive micro-agglomeration and fine particle size control.

Motor—reducer—gearing coupling—main shaft

Capacity: 0.25-60 m3/h

Drum volume: 200-1200L

What is Cyanuric Acid and Its Applications Cyanuric acid (CYA) is an…

What is Potassium Sulfate and Why Granulate It Potassium sulfate, commonly referred…

With the rise of precision agriculture and crop-specific nutrient strategies, specialty compound…

In briquetting, the binder is often the unsung hero. Whether you’re compacting…

Mixing and pelletizing processes are very important steps in the sintering production…

The Main Source of Ammonium Chloride The combined Alkali process (Hou’s process)…