Briquetting

Why briquetting?

- Creation of uniform products (size, volume)

- Reduce the volume of a powder

- Stabilise unstable mixtures

- Improve powder flow

- Keep a product dust-free

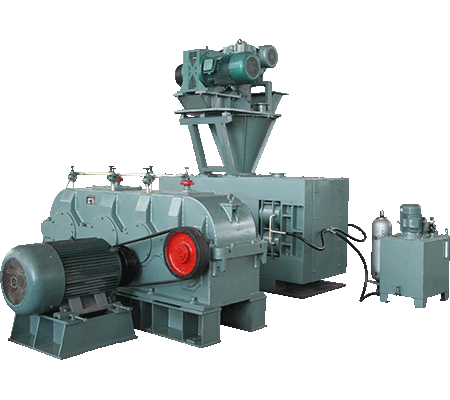

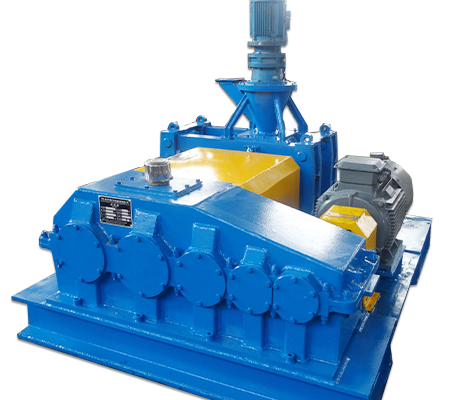

MAXTON’s briquette machines

Fields of applications

- Chemicals (sodium sulphate, sodium chloride, carbonates, sodium cyanide, potassium cyanide, iron sulphate, potassium bromide, boric acid, urea, calcium hypochlorite, etc.)

- Minerals (alumina, bauxite, lime, dolomite, china clay, magnesia, fluorspar, paint pigments, sulphur, chromium, cobalt, copper, iron, manganese, lead, zinc, etc.)

- Gypsum from power station flue gas desulphurisation

- Sponge iron

- Metallic oxides (Waelz oxides, rare earth oxides, zirconium hydroxide, ferroalloys, molybdenum trioxide, zircon sand…)

- Steel turnings

- Coal : production of briquettes for home heating or industrial purpose (partial coke oven charge, briquettes treated to obtain formcoke, briquettes for gasification)

- Coal for production of activated carbon

- Lignite, peat

- Charcoal

- Graphite, carbon black

- Coke paste

- Phosphate (hot or cold briquetting)

- Clay

- Detergents

- Frozen food

- Sugar

- Salt

- Glass batch

- Steelworks waste materials and by-products (sludge, mill dust, sintered products, mill scale, coke fînes, etc.)

- Dried sewage sludge

An Environmental Solution

- Recycle industrial waste

- Recycle beneficiated dust in an industrial process

- Eliminate pollution problems caused by airborne dust – air and ground pollution

Feasibility study

- Laboratory briquette press enables our client to conduct briquetting feasibility studies on a wide variety of products in very small quantities (about 10kg for one test)

- The studies include briquetting performance and strength tests

- If the results of the tests meet the client’s requirements, the project can move forward

MAXTON’s briquetting services:

- Design of briquetting plants

- Test runs and free feasibility studies at the workshop

- Basic and detail engineering of briquetting.

- Design and manufacture of all the equipment especially the key equipment (briquetting presses, mixers, dryers )

- Technical assistance for mounting and commissioning of the units

- Training of operators

- Supply of spare parts

- Modernisation of existing plants and equipment

- Adaption of using own briquetting technology to equipment manufactured by other makers