The pumpjack or oil pumping unit is the surface equipment used when pumping oil with the rod pump. It converts the high-speed rotation of the surface power machinery into low-speed reciprocating motion, driving the downhole pump to work through the sucker rod.

The commonly used pumping units are conventional crank-balanced units and beam balanced units, colloquially known as the “nodding donkey,” which consist of parts such as the electric motor, reducer, crank, connecting rod, and beam.

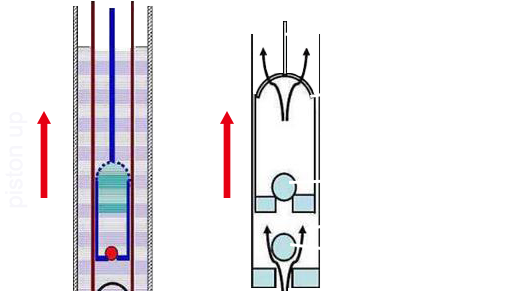

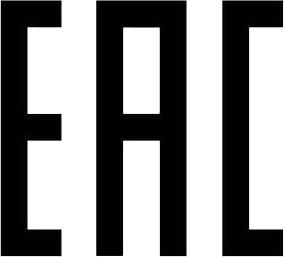

By driving mechanism (normally a motor connected to a reducer, crank-connecting rod mechanism, and horsehead), transform high-speed rotary motion into the low-speed reciprocating motion of the pumping unit’s donkey head. Through the polish rod and pumping rod, the plunger of the walking valve moves up and down in the pump barrel, achieving oil pumping.

Put the “donkey head” from top to bottom, and then from bottom to top. This movement process is called “stroke”. During the upstroke, the force of the pumping unit must be upward. In the process of falling and rising, the crude oil will be “brought up” and flow into the oil pipe.

In the downward stage of the stroke, the force of the pumping unit is also downward. During the descent, crude oil will enter through the valve. When the “donkey head” moves downward to the limit, the valve in the underground pipeline will close.

Then the “donkey head” goes up and drives the oil pump up. The oil in the pipeline can only move upward passively because the valve is closed, and finally enters the oil pipe.