The infrastructure investment in crushing and grinding systems generally accounts for over 60% of the total infrastructure investment in a mineral processing plant. Additionally, the power consumption during their operation accounts for 50% to 60% of the total power consumption in the mineral processing process. Therefore, fundamental experimental research on crushing and grinding processes and equipment in mineral processing plants has become increasingly important.

High-pressure grinding roll (HPGR) testing mainly examines the impact of changes in working pressure, roller speed, roller surface gap, and raw material moisture content on the crushing effect. The equipment provided by Maxton for laboratory testing is precisely capable of meeting this demand. It can be used to evaluate the feasibility of the high-pressure grinding rolling process, select equipment models, and determine operating parameters.

ORE CRUSHING AND GRINDING IN MINING

ORE CRUSHING AND GRINDING IN MINING  CEMENT MAKING

CEMENT MAKING  ORE GRINDING IN METALLURGY

ORE GRINDING IN METALLURGY

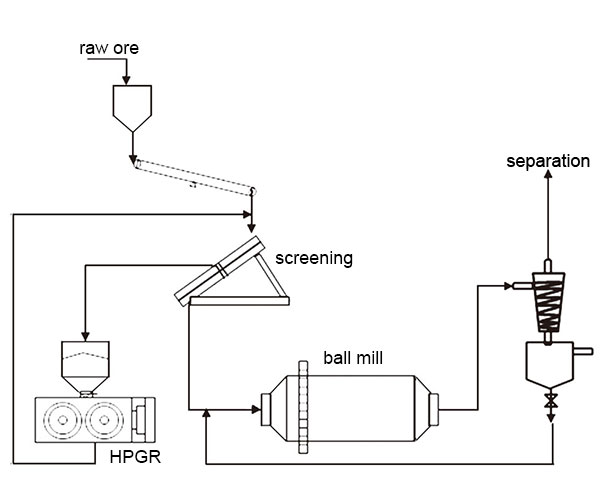

HPGR and ball mill are both widely used ore crushing (grinding) equipment.…

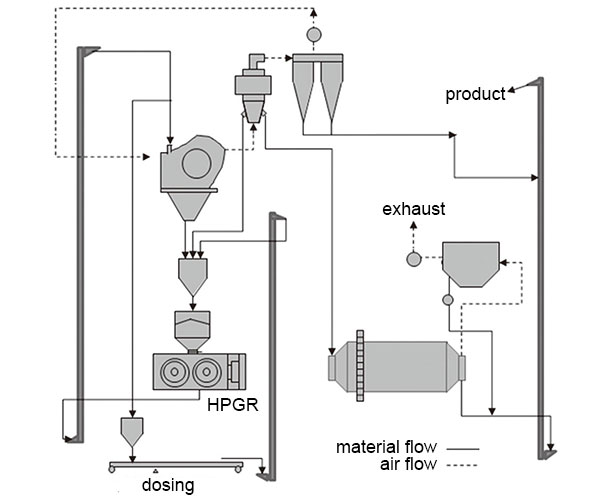

High-pressure grind roll are widely used in major mines and related material…

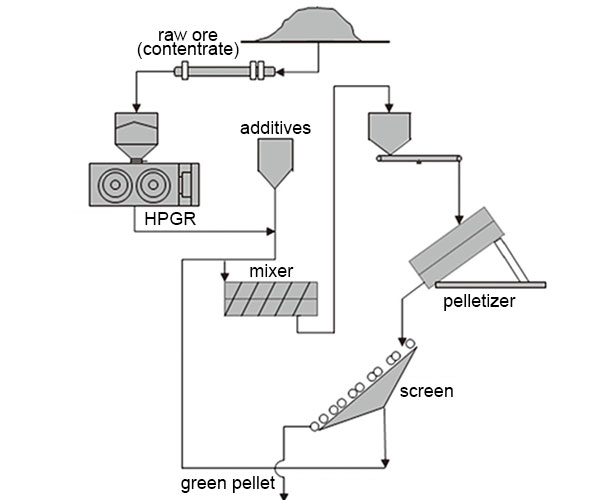

Situation on Non-Ferrous Metal Ore Grinding In the actual production of various…