Why Using Intensive Mixer in Sintering System

The sintering production process primarily involves sintering raw materials composed of iron-containing materials, fuel, and flux. The main components of iron-containing materials include various iron ores, iron ore concentrates, waste sludge, dust, and blast furnace or related furnace by-products in the plant. The main solid fuels include coke powder, coal, etc. while fluxes mainly include limestone, dolomite, and quicklime, etc.

In the sintering production process, intensive mixers are primarily used to replace traditional drum mixers for mixing and granulation. Japanese companies such as Sumitomo and Nippon Steel were the first to apply vertical intensive mixers to the mixing of sintering raw materials. After Sumitomo adopted intensive mixers for mixing and granulation at the Wakayama Third Sintering Plant, productivity increased by 8%-10% compared to using traditional drum mixers, and the coke ratio decreased by 0.5%. Intensive mixing and granulation systems have been applied at the Usiminas Sintering Plant in Brazil, the Dragon Steel Plant in Taiwan, and the ArcelorMittal Ghent Plant in Belgium, all achieving good production results.

With the development of thick-layer sintering technology and the continuous increase in the proportion of concentrate in the sintering production process, the requirements for the homogeneity of sintering raw materials are getting higher. Intensive mixers have gained increasing attention in the sintering industry due to their advantages of good mixing uniformity and high mixing efficiency.

Mechanism of Intensive Mixing for Sintering Raw Materials

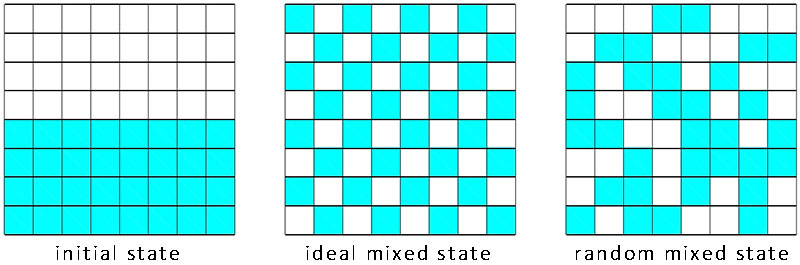

Solid mixing refers to the operation of mixing two or more different types of particles under dry or slightly moist conditions by applying external force to make them uniformly distributed. The mixing of sintering raw materials falls under solid mixing. In the mixed state, the white and blue squares in the below figure shows each represent a type of material. An ideal completely mixed state is almost impossible to achieve, and the actual mixing process of sintering raw materials is random, with the best mixing state being completely random mixing.

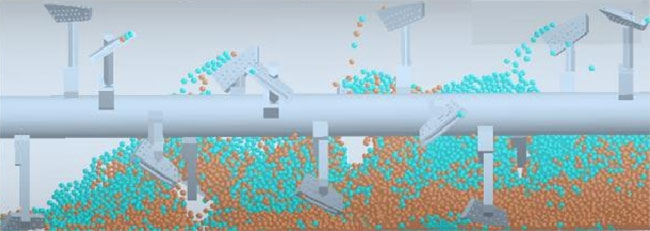

Horizontal intensive mixers are mainly used for homogenizing sintering raw materials. During operation, the driving wheel reducer drives the rotor to rotate at a certain angular velocity, and the plow head fixed on the rotor also rotates, causing the sintering raw materials to circulate turbulently along the radial direction of the drum. The sintering raw materials are thrown along the normal direction of the plow head’s leading surface, with forward plow heads moving the materials toward the discharge port and reverse plow heads moving them in the opposite direction, achieving rapid mixing with high uniformity. The primary mixing mechanisms in horizontal intensive mixers are convection mixing, shear mixing, and diffusion mixing.

- Convection Mixing: This refers to the large-scale movement of particle materials in groups under the force, mixing during the back-and-forth movement.

- Shear Mixing: This occurs when relative movement between particles forms shear planes, leading to mixing.

- Diffusion Mixing: Single particles move in all directions within a small range, similar to molecular diffusion in gases and liquids, characterized by random motion.

The Mixing Process

The homogenization process of sintering raw materials in horizontal intensive mixers involves three stages:

- Rapid Mixing Stage: In the initial mixing stage, different types of particles are completely separated, primarily undergoing convection mixing. The mixing effect is greater than the segregation effect, and the mixing variance coefficient decreases the fastest.

- Slow Mixing Stage: In this stage, particle materials mainly undergo convection and shear mixing. The mixing has reached a certain level, and the segregation effect becomes more apparent. Mixing and segregation coexist and compete, with the mixing variance coefficient decreasing more slowly.

- Dynamic Equilibrium Stage: In this stage, particle materials mainly undergo diffusion mixing, with mixing and segregation reaching equilibrium. Both processes occur at similar rates, leading the particle system to achieve a uniform state.

When stationary, the iron-containing raw materials, fuel, and flux are layered flat inside the mixer. When the rotor assembly starts rotating uniformly at a relatively high speed, the plow head first plows the bottom layer of raw material particles, throwing them along the normal direction of the plow head’s leading surface into the positions of other particle materials. Simultaneously, a groove is left under the plow head, allowing some particles in the middle layer to quickly fall into the groove, while some of the top layer of raw material particles move into the recesses of other particle materials. Under the repeated disturbances of the plow head, various particles continuously exchange positions and move towards the discharge port on the left side. As a result, the materials at all positions inside the drum become mixed, thus achieving a certain degree of mixing of the sintering raw materials in the horizontal intensive mixer.

Three Main Factors Affecting the Mixing Effect of Intensive Mixers

The mixing of particle materials is a crucial process in industrial production such as steel and chemicals, significantly influencing the quality of industrial products. The shape of particles, moisture content, and structural parameters of the mixer significantly impact the mixing rate and uniformity of particle materials in the mixer.

Factors affecting the homogenization process of sintering raw materials in horizontal intensive mixers can be categorized into operational parameters, particle physical properties, and structural parameters of the mixer. The mixer speed, moisture content of raw materials, and mixing time have noticeable effects on the mixing results.

Mixer Speed

The movement state of particle materials in the drum and the intensity of collision with the plow head are primarily influenced by the rotor speed. Therefore, rotor speed significantly affects the mixing characteristics of sintering raw materials. Increasing the speed can accelerate the homogenization rate of sintering raw materials in the mixer. This is mainly because as the speed increases, the relative movement speed between particles and the plow head increases, and the height and distance particles are thrown also increase. Concurrently, the convection mixing effect between particles intensifies, improving particle flowability and thus speeding up the homogenization process.

When the rotor speed is low, fewer particles are thrown by the plow head, with most particles only being plowed up and then sliding down the plow head’s leading surface into the grooves. The particle movement range is very limited, preventing strong convection mixing.

Moisture of Raw Materials

Moistening sintering raw materials during the mixing process enhances homogenization and granulation. A certain moisture content aids mixing and granulation because particles with a small amount of water generate liquid bridge forces.

When water is added during the mixing process of sintering raw materials, adjacent particles aggregate due to the liquid bridge force, significantly affecting the flowability and mixing performance of the materials. Under different conditions, the moisture content of sintering raw materials may either facilitate or hinder mixing.

Dry particles achieve a uniform state faster than wet particles because dry particles exhibit stronger segregation effects, reaching a uniform state quickly through competition with mixing effects. Wet particles, due to liquid bridge forces, form particle agglomerates that reduce segregation effects, requiring a longer mixing time to achieve uniformity. This implies that more water added during mixing prolongs the time required to reach a uniform state because increased moisture reduces particle movement speed and velocity gradient, thereby slowing the homogenization rate.

Adding moisture during the mixing process improves particle mixing by forming particle agglomerates through liquid bridge forces, reducing segregation effects, and enhancing the uniformity of sintering raw materials.

Mixing Time

Mixing time refers to the duration required for materials to mix uniformly in the mixer, serving as an important indicator of the mixing efficiency of sintering raw materials in horizontal intensive mixers. If the mixing time is too short, materials do not achieve uniform mixing. Conversely, if the mixing time is too long, it results in additional energy consumption, making it crucial to determine a reasonable mixing time.

The variation trend of the material mixing variance coefficient decreases gradually with time and eventually stabilizes within a range. According to measurements, a high variance coefficient in a horizontal intensive mixer can be achieved in less than a minute.