Compared to circular saws, the key advantage of band saws is their narrow kerf. This results in significantly less debris. Even as cutting capacity increases, the required machine power remains relatively low, and the machine itself is lighter. In other words, band saw machines offer a cost-effective investment.

Additionally, kerf loss directly translates to material loss. When using a band saw, this loss is minimized. This is particularly beneficial when cutting expensive materials and making long cross-cuts, making it a cost-saving solution.

After entering the process parameter data on the control panel, the band saw can operate fully automatically. The equipment also supports manual and semi-automatic operation modes, allowing users to select the appropriate mode as needed.

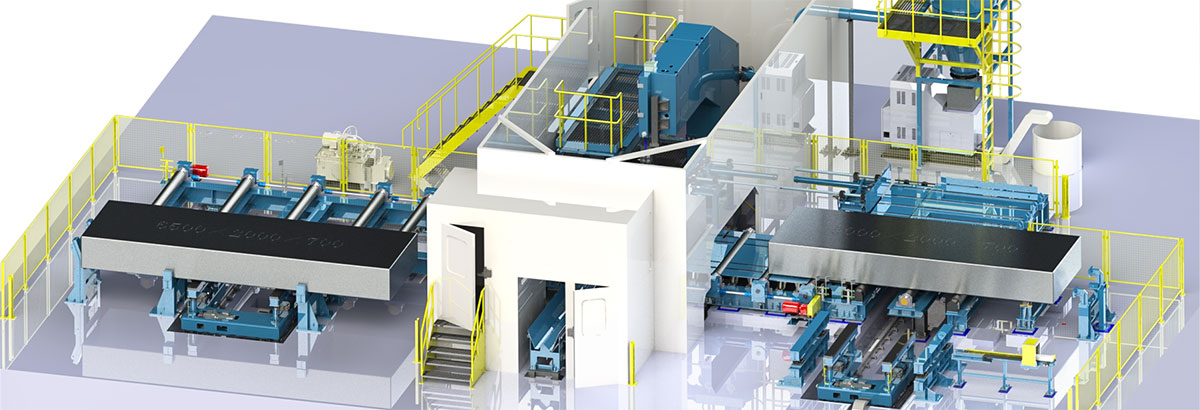

Example: Vertical high-speed band saw for aluminum slabs

First, the hydraulic ingot receiver extends outward. The ingot, transported by an overhead crane, is placed onto the hydraulic ingot receiver, which acts as a buffer. The receiver then slowly lowers the ingot onto the entry roller table.

Once the entry roller table is activated, the slab moves forward until it reaches the center of the alignment and clamping device. At this point, the roller table stops, and the slab is securely clamped.

The band saw then performs head cutting, sectioning, and tail cutting.

After the head and tail are removed, the waste material is pushed out along with the slab and transported to the designated scrap discharge position, where it is collected in a scrap bin.

Finally, the hydraulic ingot receiver extends again to lift the ingot off the pre-saw roller table, and the overhead crane transports the ingot to its designated position.

Aluminum Ingot Vertical High-Speed Band Saw

Aluminum Ingot Vertical High-Speed Band Saw  1+1 Dual-Station Vertical High-Speed Band Saw

1+1 Dual-Station Vertical High-Speed Band Saw  Copper Bar Vertical High-Speed Band Saw

Copper Bar Vertical High-Speed Band Saw  Aluminum Bar and Ingot Combined Vertical Band Saw

Aluminum Bar and Ingot Combined Vertical Band Saw  Bar / Ingot / Slice Horizontal High-Speed Band Saw

Bar / Ingot / Slice Horizontal High-Speed Band Saw  Aluminum Alloy Round Ingot Horizontal Gantry Band Saw + Peeling and Boring Integrated Machine

Aluminum Alloy Round Ingot Horizontal Gantry Band Saw + Peeling and Boring Integrated Machine  India Case

India Case  South Korea

South Korea  Iran Case

Iran Case  China Aluminum

China Aluminum