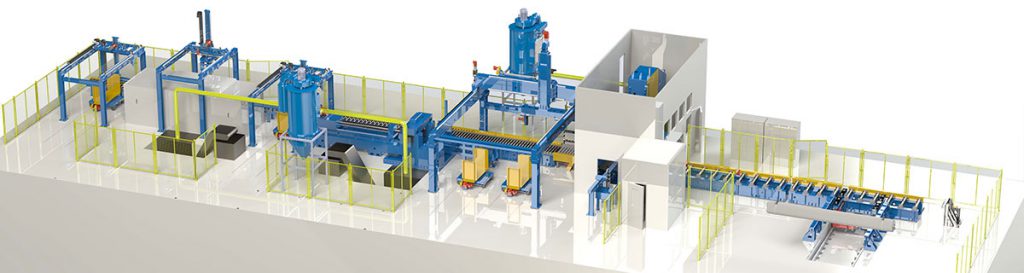

With the development of modern manufacturing, metal bars have been widely used in the industrial field. To ensure product quality, industries generally use peeling machines for surface treatment of bars, obtaining bars that meet the required dimensions and precision.

Metal turning peeling is a highly efficient surface processing technology that can quickly remove decarburized layers, cracks, and other defects from the surface of bars, achieving high-precision bright material standards. It is an effective method for improving metal surface quality, especially advantageous for processing long bars. Continuous turning of the entire bar significantly increases efficiency, making it several to dozens of times more efficient than conventional processes.

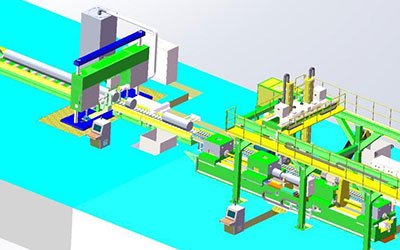

1. Feeding and Clamping

The raw bar material is first loaded into the machine through the feeding mechanism. It is positioned and firmly clamped in place to ensure stability during processing. The automatic centering system and guiding device align the material precisely with the spindle axis, preventing deviation or vibration during peeling. At this stage, auxiliary systems such as lubrication, chip removal, and dust extraction are also activated to prepare for continuous operation.

2. Peeling and Material Removal

Once clamped, the peeling tool engages with the rotating bar surface to remove the outer layer of scale, oxide skin, or surface defects. The cutting depth and feed rate are automatically adjusted according to the set parameters to achieve the required tolerance and surface finish. The continuous peeling process ensures uniform material removal along the entire length of the bar. At the same time, chips are broken down and discharged through the chip collection system, maintaining smooth and safe operation.

3. Finishing, Conveying, and Discharge

After peeling, the bar passes through a sizing and straightening section to further improve dimensional accuracy and surface quality. The finished bar is then conveyed forward to the discharge table, where it is either cut to the required length or transferred for downstream processes. At the end of the cycle, the system stops automatically, and the next piece of raw material is fed into position, ensuring continuous, efficient, and automated production.

China Aluminum (Peeling & Boring)

China Aluminum (Peeling & Boring)  Russia Aluminum

Russia Aluminum  Iran Case

Iran Case  Pakistan (Peeling & Boring)

Pakistan (Peeling & Boring)