Plough share mixer, also known as ploughshare mixer, plow mixer or plough mixer is a kind of single shaft high speed paddle mixer with high homogeneity, the degree of mixing can reach 85-95%, which means the coefficient of variation (CV) is not greater than 5-15%.

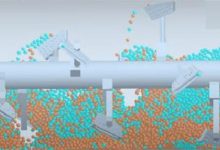

It is suitable for the mixing of two (or more) granules or powders with a particle size of more than 10μm, and the addition of a small amount of water or binder. During the mixing process, the raw materials are transferred around the drum in a radial, lateral and longitudinal movement by the high speed plough shears and choppers. Its short mixing time, especially short for free flowing powders or granules.

Raw materials are fed through the feeding port. When the motor starts, the reducer and coupling drive the main shaft to rotate, and the plows continuously mix the materials in the drum. The additive is evenly sprinkled on the turbulent materials through the liquid spray device, and is evenly mixed with the powder during the mixing process. During the mixing process, the materials are mixed mainly by shearing and convection, and supplemented by diffusion. Plow produces a strong vortex effect of colter turning on the material, which strengthens the mixing effect.

The inner side of the cylinder can be installed with choppers directly driven by motors. When mixing materials, the thrown and turbulent materials pass through the choppers, and are quickly and intensively scattered by the high-speed rotating chopper. Plow and chopper have dual effects on the material, the material can mix evenly in a short time and mixing quality is also improved.

In order to meet the needs of solid additives, the outer layer of the cylinder can be equipped with a heating device, which can be heated while the material is mixed. When a certain temperature is reached, the additive will melt, so that it can be better mixed with the material and achieve the effect of uniform distribution.

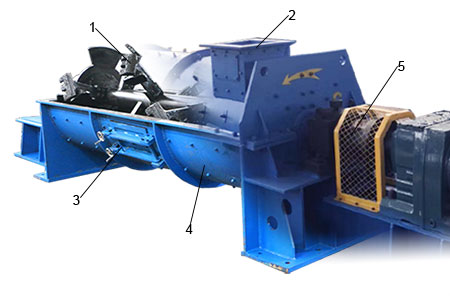

1. Mixing tool 2. Feeding port 3. Inspection door 4. Mixing drum 5. Transmission part

The mixing tool is durable and easy to maintain, and its shape can be determined according to the material being mixed. As standard, our company already offers a reliable selection of wear-resistant materials:

Rubber or polymer lining to prevent materials from sticking

Power demand, speed, etc. can be selected according to specific working conditions.

The power system can choose electric motor or hydraulic motor according to the needs, and the transmission system can choose direct connection, V-belt or hydraulic coupler (normally direct connection for small models, V-belt for medium models, and hydraulic coupler for big models).

Continous design

Continous design  Batch design

Batch design  High temperature mixing (batch type)

High temperature mixing (batch type)  Customized special design for special application

Customized special design for special application Different working conditions require different equipment. Even equipment with the same main structure has various configurations. The complexity of mixed operation conditions determines the diversity of equipment.

The equipment capacity ranges from 200kg/h lab test machine to 700t/h large mixer.

With or without

| Model | Drum volume (L) | Capacity (m3/h) | Power (kW) | Dimension L*W*H (mm) |

| M15D | 150 | 4-5 | 4-5 | 2350*800*950 |

| M30D | 300 | 8-10 | 7.5-11 | 3250*900*1250 |

| M60D | 600 | 16-25 | 15-18.5 | 3726*1200*1340 |

| M90D | 900 | 25-30 | 37 | 4133*1511*1311 |

| M120D | 1200 | 35-37 | 37-45 | 4286*1300*1400 |

| M200D | 2000 | 58-60 | 55-75 | 5122*1450*1640 |

| M300D | 3000 | 85-95 | 75-90 | 6199*1550*1790 |

| M420D | 4200 | 120-130 | 110-132 | 6874*1600*1890 |

| M600D | 6000 | 160-180 | 160-185 | 7571*1750*2040 |

| M800D | 8000 | 230-250 | 220-250 | 8219*1860*2040 |

| M1000D | 10000 | 280-300 | 280-355 | 8850*2080*2100 |

| M1350D | 13500 | 405 | 355-450 | 9356*2150*2200 |

| M1500D | 15000 | 450 | 450-560 | 10450*2150*2200 |

| M2000D | 20000 | 600 | 630-800 | 11250*2350*2300 |

MAGNESIA & WATER

MAGNESIA & WATER

MILL SCALE & BINDER

MILL SCALE & BINDER  LATERITE FERRONICKEL ORE & BINDER

LATERITE FERRONICKEL ORE & BINDER  DRI & BINDER

DRI & BINDER

Producing high-quality dry powder fire extinguishing agents requires not only the right…

Energy demand continues to grow worldwide, and industries are under increasing pressure…

Why Using Intensive Mixer in Sintering System The sintering production process primarily…

Mixing and pelletizing processes are very important steps in the sintering production…

With the intensification of the energy crisis, coal prices have risen sharply. At…