What is Potassium Sulfate and Why Granulate It

Potassium sulfate, commonly referred to as SOP, is one of the most important chlorine-free potash fertilizers used in modern agriculture. It provides not only potassium, but also sulfur and magnesium, which are essential nutrients for crop growth. SOP is particularly suitable for sensitive crops such as tobacco, citrus, potatoes, apples, and a wide range of field crops including rice, cotton, and corn.

Traditionally, SOP has been supplied in powder form. While powdered SOP is relatively easy to mix, it suffers from several drawbacks during handling and use. Powder tends to cake during storage and transport, making it difficult to spread evenly. During application, dusting occurs, which not only causes product loss but also environmental pollution and health hazards to workers. In addition, powders are difficult to use in mechanized fertilization, and nutrient efficiency is lower due to faster leaching losses.

Granular SOP overcomes these disadvantages. By converting SOP into granules, flowability improves, dust is reduced, caking is avoided, and mechanized spreading becomes possible. Granules also act as a slow-release fertilizer, prolonging nutrient availability to crops and improving fertilizer utilization efficiency. This is why dry granulation using roller compactor technology has become the mainstream solution for SOP producers worldwide.

Properties of Potassium Sulfate (SOP)

The physical and chemical properties of SOP are crucial for understanding its granulation behavior. SOP is usually colorless or white, occurring as hexagonal or orthorhombic crystals, granules, or powder. It is odorless, bitter in taste, hard in texture, and stable in air.

Molecular weight: 174.27

Density: 2.66 g/cm³ (at 20℃)

Melting point: 1069℃

pH: about 7 in aqueous solution

Solubility: 1 g SOP dissolves in 8.3 mL of water, 4 mL of boiling water, or 75 mL of glycerol; it is insoluble in ethanol, acetone, and carbon disulfide.

These properties explain why SOP requires precise control during granulation. The relatively poor plasticity of SOP crystals means that high pressure is needed to form dense granules. At the same time, water acts as a natural binder but must be carefully controlled to avoid sticking and energy loss during drying.

Advantages of Granular SOP

Granular potassium sulfate offers multiple advantages compared to powdered form:

- Improved handling and storage: Granules resist caking and remain free-flowing even during long-term storage and transportation.

- Reduced dust and loss: Granules minimize dusting during application, reducing product loss and improving environmental safety.

- Better suitability for mechanized fertilization: Granules can be spread more evenly using modern machinery, ensuring more accurate application rates.

- Slow-release characteristics: Granules release potassium and sulfur more gradually, improving nutrient use efficiency and reducing leaching.

- Price and performance benefits: Although granulation adds some cost, the improved efficiency and reduced waste give granular SOP a stronger price-to-performance ratio compared to powders.

Strength Requirements and Quality Standards

The strength of SOP granules is one of the most important indicators of product quality. Weak granules break easily during packaging, transport, or spreading, leading to dust, uneven application, and customer dissatisfaction.

Most producers adopt standards requiring:

Premium-grade Granule strength ≥ 30 N

Abrasion loss ≤ 2% when reaching the customer

These requirements ensure that the final product maintains integrity throughout its lifecycle, protecting both market reputation and economic value.

Dry Granulation with Roller Compactor: Principle and Process

The most widely used method for SOP granulation is dry granulation with a roller compactor. In this process, powdered SOP is fed between two counter-rotating rollers under high pressure.

As the rollers compress the powder:

- The air between the particles (60%–70%) is expelled.

- Capillary and surface water is squeezed to the outer surfaces.

- Particles are broken, rearranged, and compacted.

- Mechanical interlocking and van der Waals forces bind the particles together.

The result is dense compacted sheets or blocks, which are then crushed into granules. These granules are screened to obtain the desired size range and dried to remove excess moisture. The roller compactor is the heart of this system, and its pressure control directly determines granule quality.

Key Factors Influencing SOP Granulation

Several process parameters must be carefully controlled to achieve optimal SOP granulation:

Moisture content: Moisture plays the role of a natural binder in the compaction process. If it is too low, granulation efficiency will decrease. If it is too high, sticking to the rollers and higher drying costs may occur.

Compaction pressure: Adequate pressure is essential to ensure that the powder particles are compacted into strong granules. Insufficient pressure leads to poor granulation, while excessive pressure risks block breakage, demolding difficulties, and accelerated equipment wear.

Particle size of feed: Feed material should fall within a proper size range to balance compaction and crushing energy. Too fine particles trap excess air and cause vibration, while overly coarse particles require more crushing energy and reduce efficiency.

These factors interact closely, and only by maintaining the right balance can consistent, high-quality SOP granules be achieved.

Types of SOP Dry Granulation

SOP Roll compacting

In this method, the roller compactor produces strips, flakes or blocks, which are then crushed, screened, and even polished into irregular SOP granules.

Advantages: very high throughput (30 t/h or more), mature technology, easy to automate.

Application: preferred choice for large-scale SOP fertilizer producers.

Small Granulator

Another method is to use a small granulator system to directly form smaller, more rounded SOP granules in a single step.

Advantages: compact equipment layout, one-time forming, lower investment.

Limitations: capacity is small, limited by roller diameter. Industrial-scale production often requires multiple small granulators in parallel.

Challenges in SOP Granulation and Current Limitations

Despite its advantages, SOP dry granulation faces several challenges:

Particle shape and uniformity: SOP granules tend to have lower roundness and broader size distribution compared to urea or ammonium phosphate, which can cause segregation in compound fertilizers.

Binder addition: Some processes use binders to improve granule strength, but this lowers the effective nutrient content.

Capacity limits: Small granulator systems are limited in scale, while large roller compactors require higher investment and precise operation.

Addressing these challenges requires continuous innovation in roller compactor design and process optimization.

Market Outlook and Price Competitiveness

The demand for granular SOP is expanding rapidly both domestically and internationally. Key drivers include:

- Faster land transfer and expansion of planting areas

- Rising international agricultural production costs

- Increased mechanization of fertilization

- Diversification of fertilizer granulation requirements

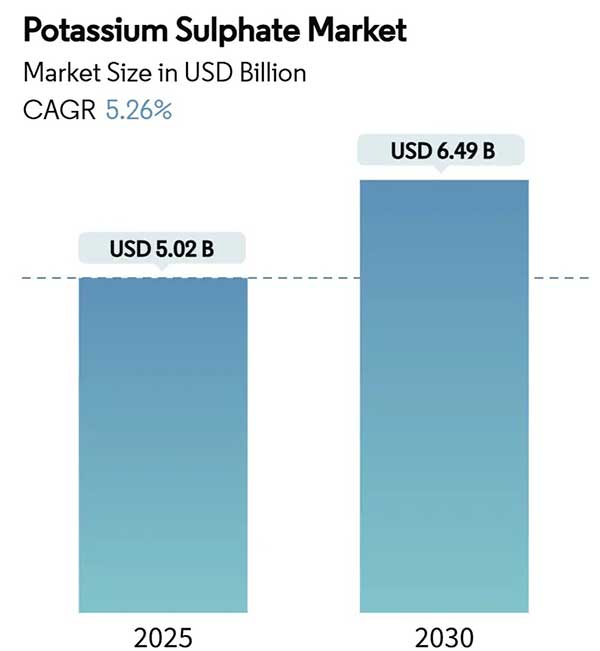

With these factors, granular SOP has a broad market space. According to Allied Market Research, the global potassium sulfate market is projected to grow from USD 4.5 billion in 2022 to USD 7.2 billion by 2032 (CAGR ~4.8%). Mordor Intelligence also forecasts a CAGR of ~5.3% between 2025 and 2030, driven by demand from high-value crops and precision agriculture. Dry granulation with roller compactors therefore provides producers with a cost-effective way to meet this demand, maintaining strong price competitiveness as reduced fertilizer losses and higher efficiency offset production costs.

Maxton Potassium Sulfate Granulation Equipment

Maxton offers both integrated SOP granulation systems and standalone roller compactors tailored for potassium sulfate dry granulation.

Integrated Systems: From raw material feeding to compaction, crushing, screening, and drying, Maxton provides turnkey solutions designed for efficiency and reliability.

Roller Compactors: As the core equipment, our roller compactors deliver stable pressure, consistent granule strength, and long service life.

Small Granulator Options: For smaller capacities or pilot-scale production, Maxton also provides compact granulation solutions.

Our systems are engineered for stable operation, high-quality granules, and competitive price, helping producers achieve both performance and profitability in the growing SOP market.

Why Dry Granulation with Roller Compactor is the Future of SOP Production

Potassium sulfate dry granulation, especially with roller compactor equipment, has become the mainstream technology for SOP production.

Roller compacting provides high capacity and mature automation.

Small granulators offer compact, low-investment solutions but with capacity limits.

The future lies in advanced roller compactor systems that improve granule roundness, narrow particle size distribution, scale up capacity, and maintain strong granule strength without sacrificing nutrient content.

With its integrated solutions and reliable roller compactors, Maxton is well positioned to support fertilizer producers in meeting the rising global demand for granular SOP.